Cementitious Urethane Coatings for Cold Storage Concrete Floors

Of the many industrial and commercial industries that require concrete flooring solutions, the food industry is perhaps one of the most important. The reason being that the floors must be sealed to prevent bacterial growth, as well as easily be made easy to clean and maintain to keep the facility sterile.

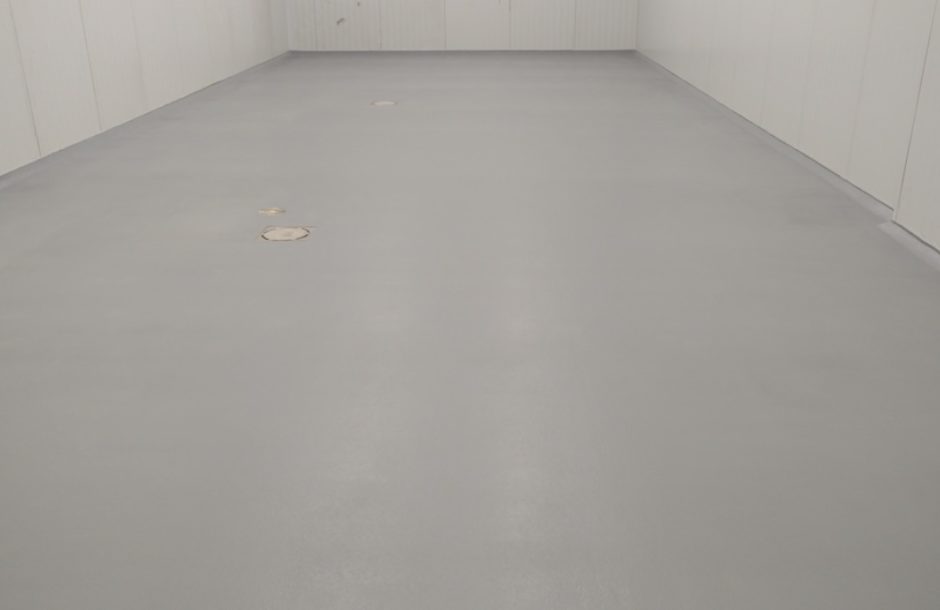

Lakeside Painting recently undertook two nearly identical concrete flooring projects for two cold storage facilities in Milwaukee, Wisconsin. Both companies feature production lines for food preparation, with one working in pasteurization, while the other makes sandwiches. Both storage facilities are kept cold, typically just above or at freezing temperature. Both areas are cleaned weekly with high-pressure steam, so the flooring systems had to be able to withstand thermal shock.

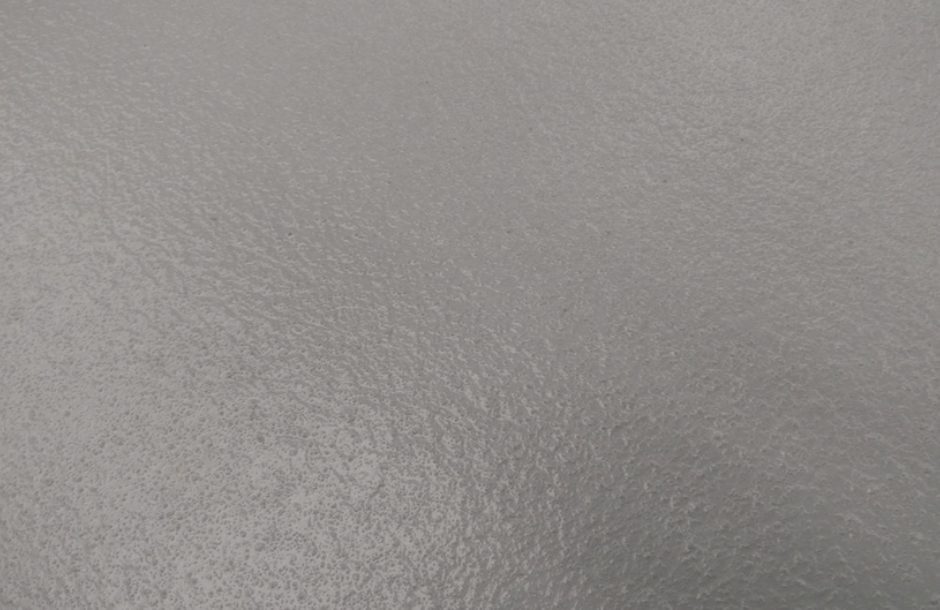

Since epoxy coatings for concrete floors must be applied at temperatures above 65° Fahrenheit, most of these finishes do not hold up well to the weekly thermal shock. As a result, the coating of choice is cementitious urethane, which was originally developed specifically for the food and beverage industries to withstand the weekly steam cleanings. Also known as urethane concrete or urethane mortar, the coating is an admixture of urethane, Portland cement, water, aggregate, and some other fine materials.

Apart from this coating’s ability to take repeated thermal shocking cleanings, it also stands up to food acids that can degrade a floor over time. Cementitious urethane also functions as a non-slip surface, which will help keep employees safe.

The Cementitious urethane product we used for these two cold storage flooring systems was Poly-Crete by Dur-A-Flex. The prep work is the same as any floor coating project: we clean, patch, and grind the floor to create a profile upon which the projects can properly adhere. We then apply a case coat of Poly-crete at 3/8″, followed by a topcoat of Colorfast at approximately 8mils. And at one of the facilities, we installed an integral cant cove about three inches up the walls to contain water that is used during the thermal shock cleaning process.

To sum it all up, if your industrial facility—especially if it is used in food and beverage production—requires a new flooring system, then cementitious urethane. It’s robust, easy to clean, and makes your facility look great.

If you need a cementitious urethane coating or any other type of concrete flooring system, don’t hesitate to get in contact with us at 262-642-9445, or email us at info@lakesidepainting.com—either way, we would be happy to discuss the process in more detail, and what are the best options for your industrial or commercial floors.